SCHAUENBURG Industrietechnik develops innovative material and functional solutions for you at the most modern production facilities with the highest level of engineering competence and comprehensive know-how for elastomers and thermoplastics. Many years of experience and specialisation as well as detailed market knowledge of the various company divisions lead to the successful bundling of synergies and to joint success. As a customer you benefit from the continuous exchange of experience and knowledge transfer. With SCHAUENBURG Industrietechnik you have access to all the services and capacities you require.

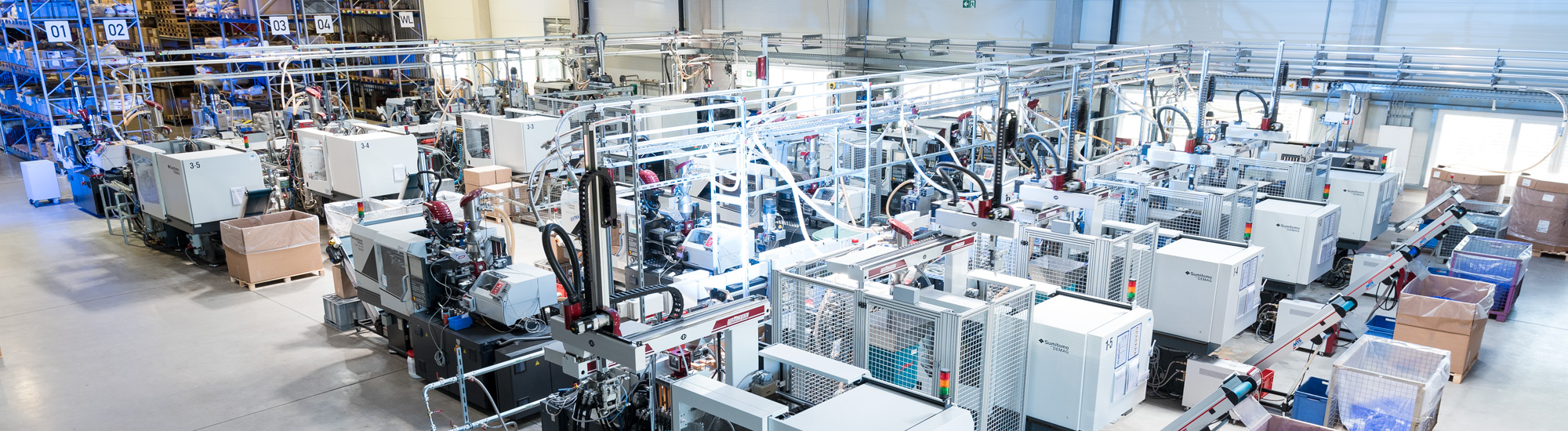

Plastic injection moulding

As a specialist for moulded parts, we supply you with tailor-made products based on rubber and plastic. The machinery of SCHAUENBURG Industrietechnik is technically state-of-the-art. A total of 22 machines are used in the production of stamped and moulded parts, which produce 24/7 fully automatic, drawing-based plastic moulded parts. The company thus has a high in-house capacity for the high-quality and on-time production of versatile moulded parts. Injection moulding machines and CNC production facilities are highly efficient for the manufacture of a wide variety of moulded parts. The economic combination of engineering and subsequent in-house production saves time and costs.

Hose line – a safe connection

With market-driven hose solutions, the VIGOT® brand convinces in all major industries such as automotive, shipbuilding, steel industry, food industry or aerospace. Original equipment, drawing-based hose line or replacement hose line, in the workshops, hoses from DN 2 to DN 300 are manufactured and assembled with the corresponding fittings. Special designs according to customer requirements for individual operating applications are just as much a part of the range of services as different connection techniques. They are assembled as plug connections, clamp fastening, reusable screw fittings, crimp connections or welded fittings on metal hoses.

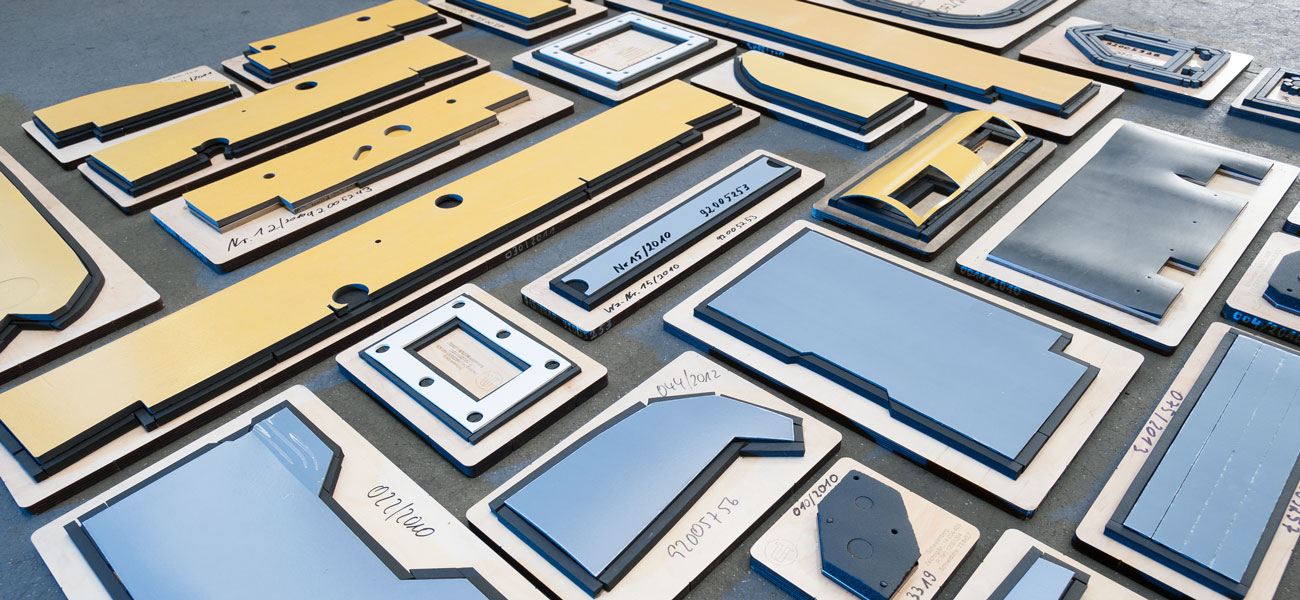

Sealing technology

One of the main products of SCHAUENBURG Industrietechnik is individually manufactured stamped parts. We develop and produce for you according to your specifications from prototype to large series. No matter whether you need ring gaskets, insulating parts, flat gaskets, sealing frames, stamped gaskets, cut-to-size parts, strips or larger plates - in our production facilities we manufacture your stamped parts to fit exactly and in the exact quantity required. Depending on the requirements, the stamped parts are produced on different machines, such as a CNC punch, a swivel arm punch, a bridge punch or a cart beam punch. Depending on the design, we work with specially produced single, double or even quadruple tools for the production of the punched parts.

Our technical sales department will be pleased to answer your questions about our production including manufacturing and assembly. Click here to access our contact form.