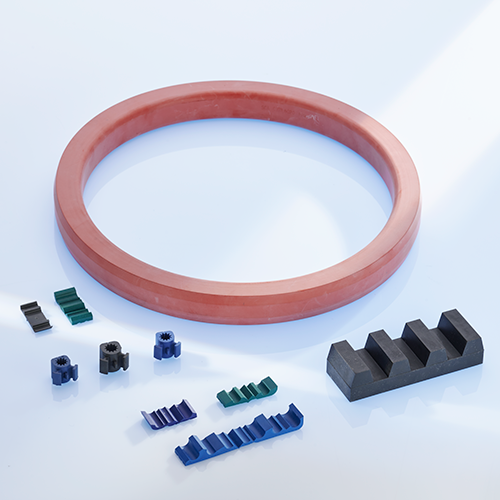

Moulded parts made of rubber, fluororubber or silicone

Moulded parts made of rubber, fluororubber or silicone play a major role in industrial engineering. They are used for a wide range of applications, from sealing pipes and tanks to manufacturing rubber bushings for machinery. Depending on the choice of raw materials, these components offer different advantages, such as flexibility, resistance to heat, cold and chemical influences, or particularly high durability and resistance.

At our facility, we specialize in the production of custom-molded parts, designed precisely to suit specific installation scenarios. Below, you'll find a comprehensive overview of our standard elastomer materials, accompanied by their unique properties, certifications, and areas of optimal application