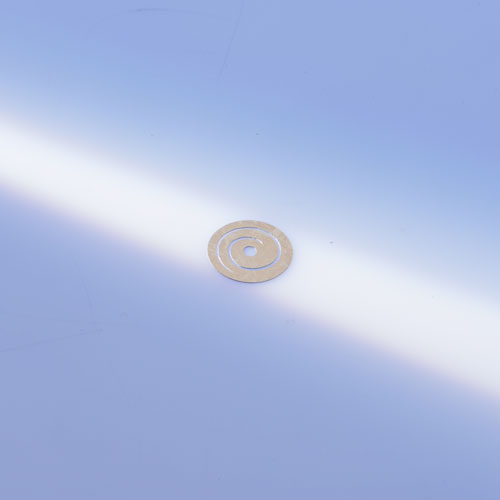

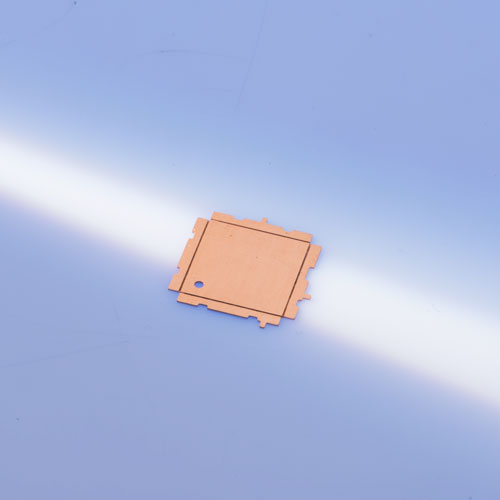

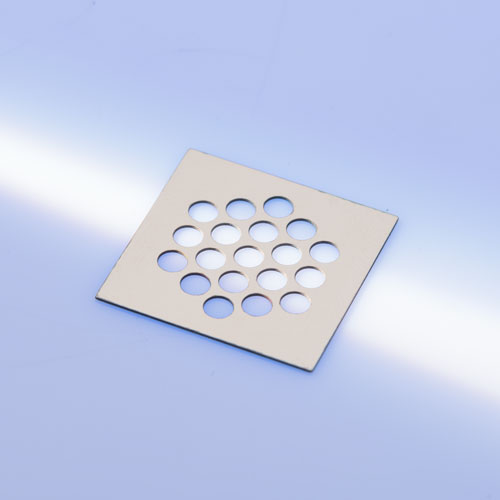

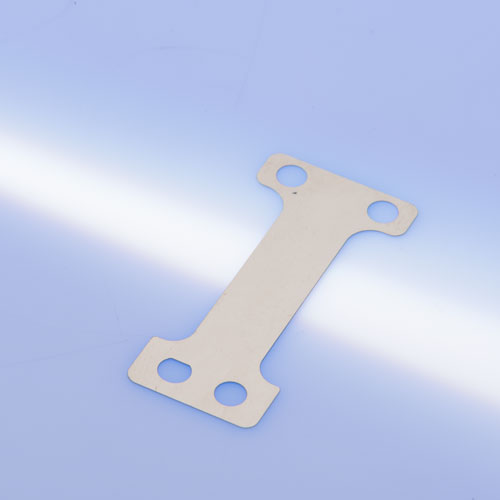

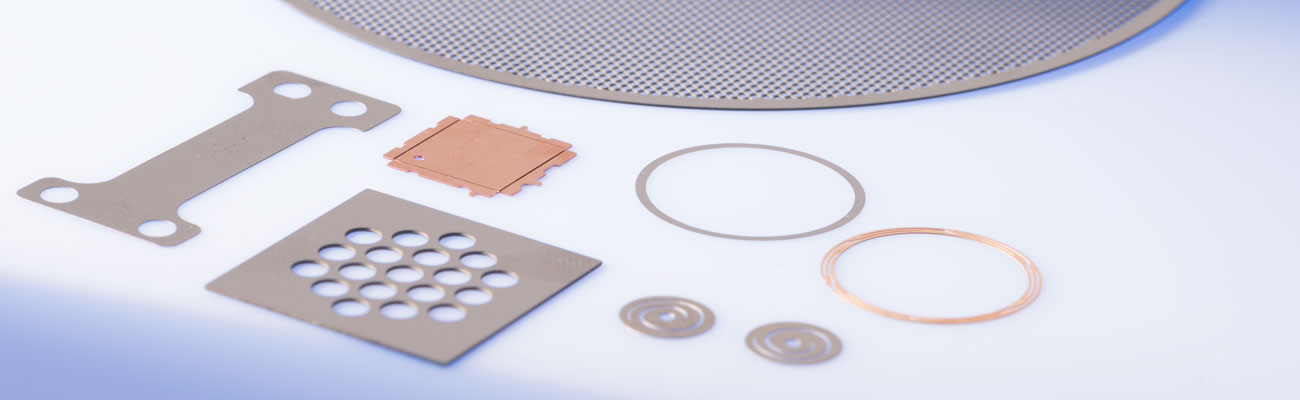

In the etching process, an acid dissolves the unprotected areas of a metal surface to create a predefined component. Materials used for this purpose include steel, CK steel and tool steel, stainless steel, nickel, nickel silver, copper, brass and bronze. Special materials such as gold, silver, titanium, aluminium and molybdenum are used as well.

Etching technology meets the highest demands in regards to quality standards. Minimal tolerances can be met even with extremely low material thicknesses of just 0.003 mm. From prototypes to large series, you benefit from the low cost of this method regardless of the quantity. Data and drawings are prepared using computer systems. Virtually any contour can be fabricated according to your models, absolutely free of burrs. The base material is not subject to any thermal changes whatsoever. This results in premium components with maximum cost effectiveness.

Please talk to us about your needs and ideas! Our engineering expertise makes us a reliable partner for all projects right from the start.