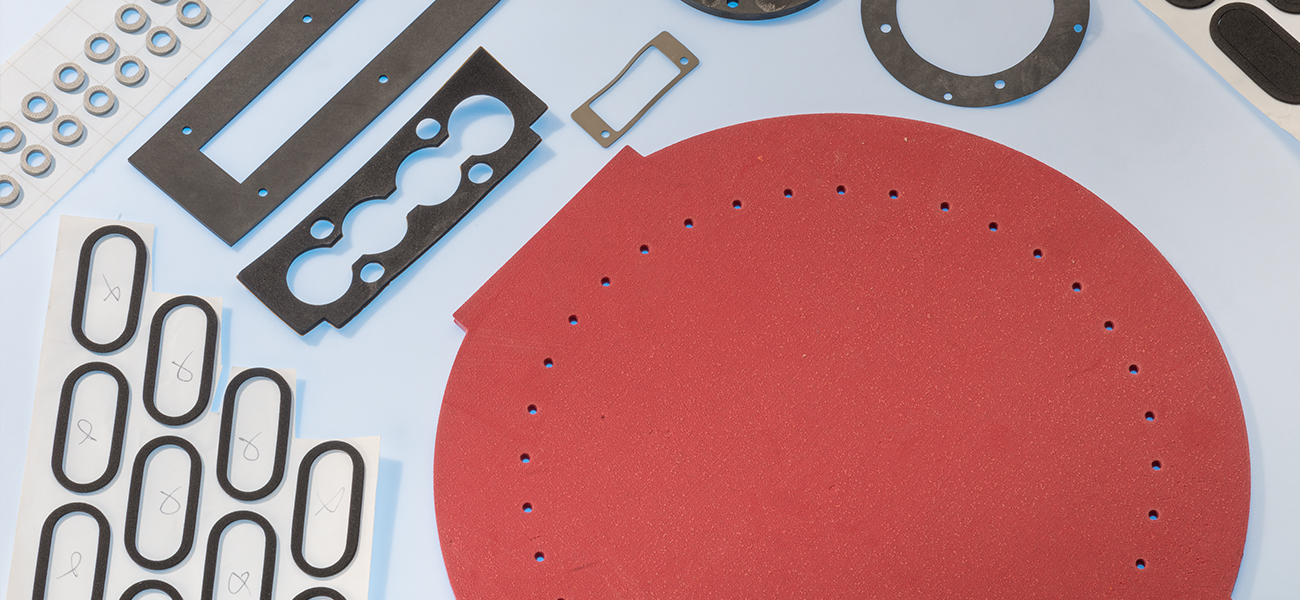

Professional sealing solutions for every application

Individually produced stamped parts in sealing technology are one of the main product areas of SCHAUENBURG Industrietechnik. We manufacture gasket frames, insulating parts, flat gaskets, ring gaskets, stamped gaskets, blanks, strips or larger sheets at any time for a precise fit and without excess production. The gaskets can be delivered in different thicknesses and - depending on the material used - also with absolutely smooth edges.

By using the most modern manufacturing processes and operations in the production of stamped parts, we have a particularly broad product portfolio. We develop and produce stamped parts according to individual specifications, from prototypes to large-scale production. With our many years of experience in engineering, we are also very happy to support customers in the development of prototypes.

Diversity in raw materials and production techniques

Various raw materials are used for the production of stamped parts. Common materials range from rubber to silicone to plastics. Specifically, we mainly use cellular polyethylene, cellular rubber, sponge rubber, NR/SBR, silicone, insulation materials, EPDM, NBR/SBR and EPDM/SBR as well as CR in production. On request, we will also be happy to use other raw materials of your choice. Or we can consult you to find the right raw material and optimum manufacturing process for your new seals.

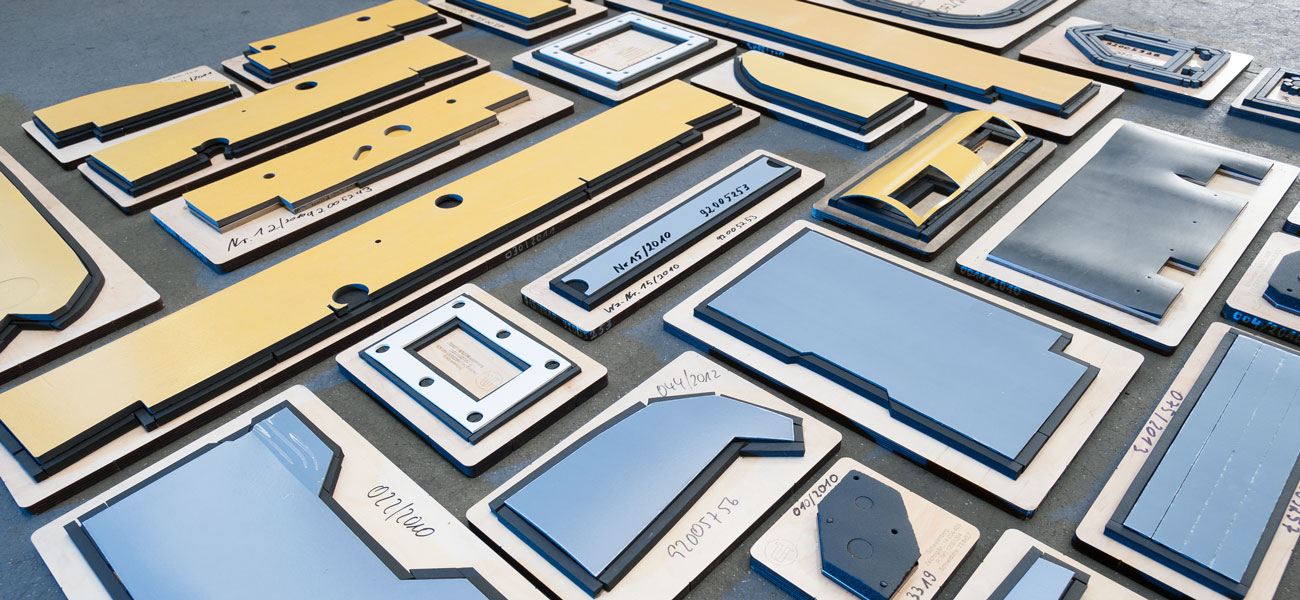

For production, we use our state-of-the-art machinery, which includes CNC punching, swivel arm punching, bridge punching and cart beam punching. We carry out the production with newly manufactured single, double or even quadruple tools. Thus, the machining process is carried out only with tools that exactly match the desired shape and size of the stamped parts.

Produktionsmethoden in der Dichtungstechnik

- CNC-based flatbed die cutting

- Rotary die cutting

- steel rule cutting

- Plotting

- water jet cutting

The wide variety of technologies used enables us to implement even highly complex sealing systems without any problems. Whether small or large series, our production results always meet all specifications precisely and down to the last detail.

Seals for different applications and industries

Rubber stampings and plastic stampings from SCHAUENBURG are used for an extremely wide range of applications. They are used, for example, as rattle and vibration protection, for sealing, insulation, cushioning or as spacers. For other applications, we also use foamed materials in addition to the usual fabric composites. Our stamped parts are particularly appreciated by customers from sectors such as automotive, the food industry, the chemical and steel industry, mechanical engineering, the electrical industry or aerospace.